WOW, its coming together just fine! We’re on the home stretch.

Months of hard work appear to be paying off and we’re seeing the benefits. I guess it reminds me of being a kid, assembling a glue together toy model. Its much the same feeling because you find it hard to lay down your tools and go home at the end of the day, you want to keep on going but you know you can’t, you’re delayed until other parts are installed first. As a kid the glue never dried fast enough for us.

I guess in the long run we all have the kid in us and I think it’s a good idea to keep it in as long as we can.

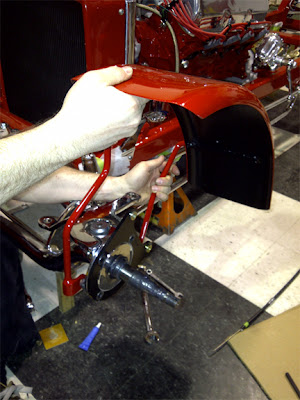

At this time we are going through the entire front-end, tightening all the bolts, setting the King Pins, shimming the King Pin bearings in preparation for the fender installation. Many special stainless bolts had to be ordered, sanded and then polished to a chrome finish. Our Fenders have to go on before the Rotors are installed.

Extra care is taken to install the freshly painted fenders. We are hoping that they will fit and align up as they did before taking them to paint.

Both fenders are now installed and it looks like we got the final fit and alignment right.

The Headlight has been waiting a long time to be installed and now it’s resting on its chrome perch. It looks absolutely awesome.

We ran into a problem installing the wiring to the headlights. We couldn’t find a professional casing long enough to house the 5 wires going to the frame. After studying the issue we went out and purchased a stainless cable kit made for similar headlights. This new system caused us to drill a ½” hole in the backside of the light casing. The lights we have were designed for the wiring to exit through the bottom bolt that attaches everything to the headlight mount but the long mounting bolt caused problems as well. This new system actually looks great. I know we did the right thing.

Its time to install those big boots, 15” X 31” – 18” wide Mickey Thompson tires. We’ve had them on and off so many times its nice to finally put them on permanently.

|

| Installing the front tires |

It’s a 20” Drive Shaft, custom made to order with a little silver paint just so it fits in with all the other running gear fittings.

Installing the self-adhesive fabric webbing to the frame. This webbing lies between the body and the frame and sort of acts as a cushion. Rather than mounting the body directly to the chassis and possibly creating friction we now have a squeak free mount. It must be the way they did it in 1923

We’ve got ourselves a rolling chassis and it’s beginning to look like we’re on the home stretch. We’re not fooling ourselves; we know there’s a lot of hard work ahead of us but its sure feels good to get things to this stage.

Before we can install the body we need to attend to a few things that are still incomplete located on the frame - next on our to do list is:

- Finish the Brake lines and bleed the brakes

- Install the Emergency brake cables and cut them to length

- Install the Speedo to Transmission gear attachment

- Install the Fuel line and Electric fuel pump that will be mounted at the rear

- Route the heavy 8 gauge Battery cable that goes directly to the starter from the rear of the Rod – the battery will be located inside the truck bed

The bodies has been placed on the frame temporarily, we’ll be removing it for final frame wiring and finishing etc. Just wanted to show everyone how it looks.